E m a i l :sale@ailutaike.com

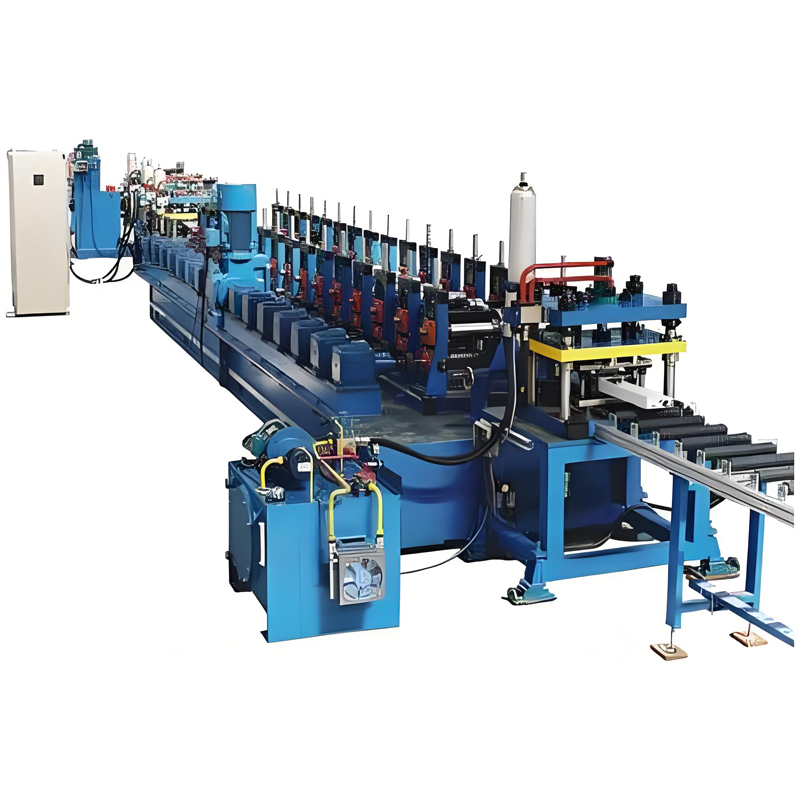

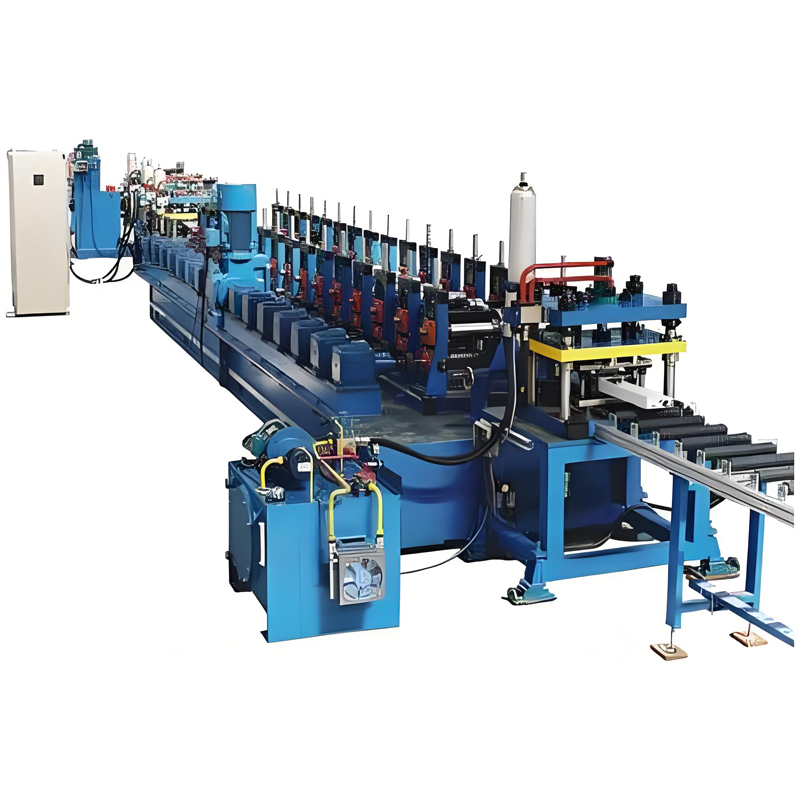

Technical requirements of the equipment

1. Technical conditions of the equipment:

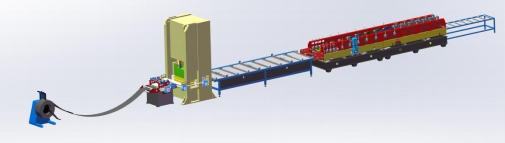

2. Floor area of the equipment: 351.51.6 (length, width and height) meters.

3. Equipment feeding direction: left in and right out.

4. Voltage parameters of 380,50Hz, and 3 phase.

5. Hydraulic oil: 46 # hydraulic oil.

6. Gear oil: 18 # hyperbolic gear oil.

Main technical parameters of the equipment

1. Width of rolled strip steel: 150-700 mm

2. Thickness of rolled strip steel: 1.2 (± 0.03) - -2.0 (± 0.03) mm

3 rolled strip steel quality: Q235B cold rolled strip, hot rolled strip, galvanized plate.

4. Online punching, production speed: 6-8 m / minute.

5. Length of rolling workpiece: 3,000 mm

6. Motor explosion-proof grade is ExdIICT4

7. Motor protection grade IP55

8. Total installed equipment capacity: about 40KW.

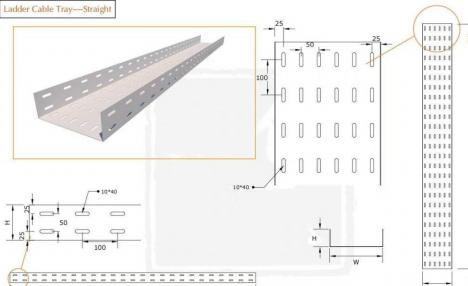

9. Material type diagram

Range of rolled products

The stamping forming unit can roll the maximum thickness of 2.0mm steel products, and can produce 50-500 bottom side 50-50-100 strength steel products. The tolerance requires a length and width of (± 1) and an angle of 90 ° ± 2 °

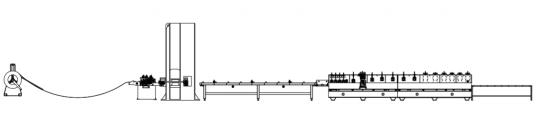

process flow diagram and layout

Punch process: active feeding- -leveling servo feeding- -punch (punching, cutting off) - -conveying platform- -forming- -discharging

Scope of supply of molding equipment

name | Optional type |

Material rolling machine | 1. Maximum load-bearing capacity: 6T 2. Maximum material coil width: 12-850mm 3. Internal diameter of material coil: φ 460-520 mm 4. Outer diameter of the material roll: 1,600 mm 5. Hydraulic pressure tightening, electric material discharge |

Flat servo feeding machine | 1.8 Roll calibration 2. Flat roller diameter: 90mm 3. Flat level motor: 4KW |

punch | 160, tons of punch press |

High-speed platform | 1. Heavy-duty roller wheel feeding: 6 meters 2. Power of the main motor: 1.5KW 3. Electric open and closing motor power: 0.75KW |

Roller pressure forming part | 1. Shaft diameter is φ 65mm 2. 2. Shaft material: 45 # steel 3. 3. Number of forming path: 15 4. Power of the main motor is 5.5KW 5. Automatic open and close motor is 1.5KW 6. Roller material: Cr 12 7. Roller hardness HRC 58-62 |

Discharge platform | Platform 1.3 meters 2. Roll type 3. No power |

hydraulic pressure station | Multiple sets of solenoid valves electromagnetic relief valve coolant passage Motor power (5.5) KW Tank capacity (300) liters |

Forming specifications | Botside 50-500 Help with a high of 50-100 |

Roller pressure thickness | 1.2—2.0mm |

Roller pressure speed | And 6-8 m / min |

Schematic diagram of the molding scheme

tooling samples