E m a i l :sale@ailutaike.com

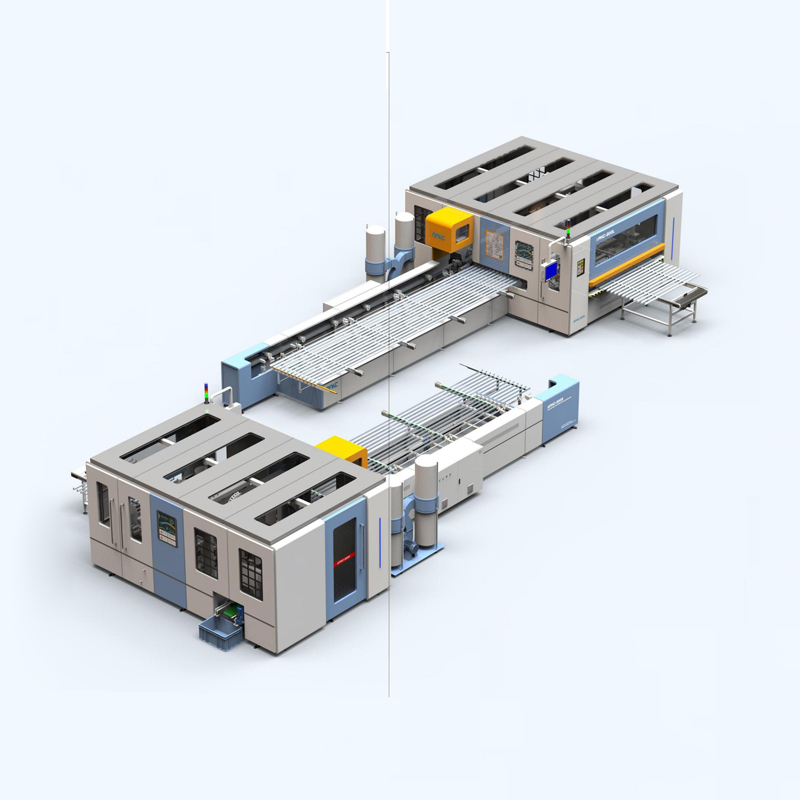

equipment characteristic:

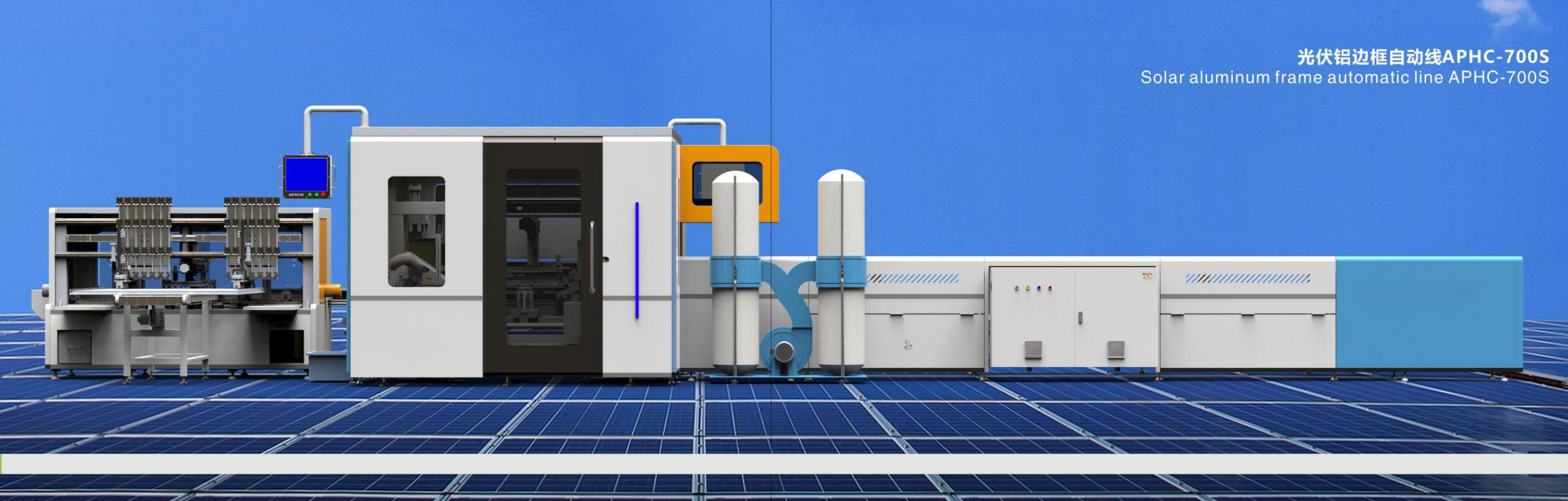

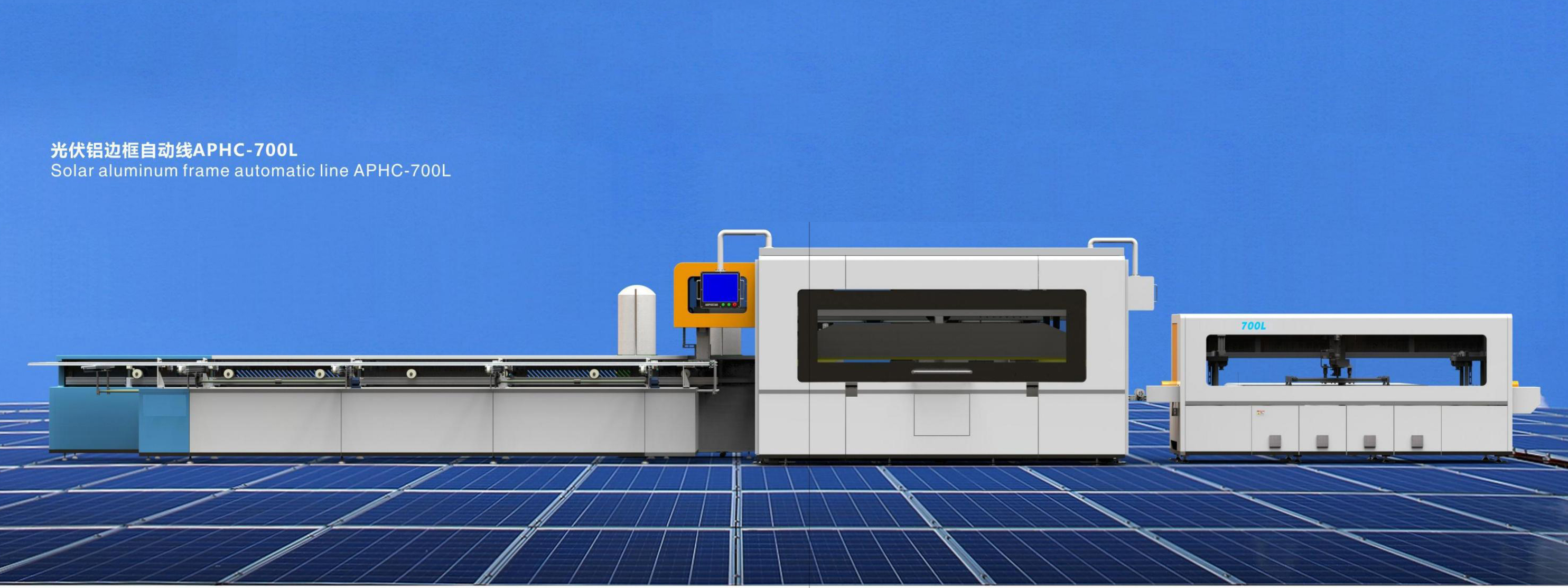

This line is suitable for the cutting and stamping function of photovoltaic aluminum frame (long frame and short frame).

Fully automatic model, profile automatic input, automatic cutting, automatic stamping, automatic output, using touch screen operation, industrial computer control program, to ensure good Good continuity and stability.

The special high precision alloy saw blade is used to ensure accurate cutting precision, high spindle precision, ensure smooth rotation of saw blade, effectively improve the smoothness of profile cutting surface Burnless.

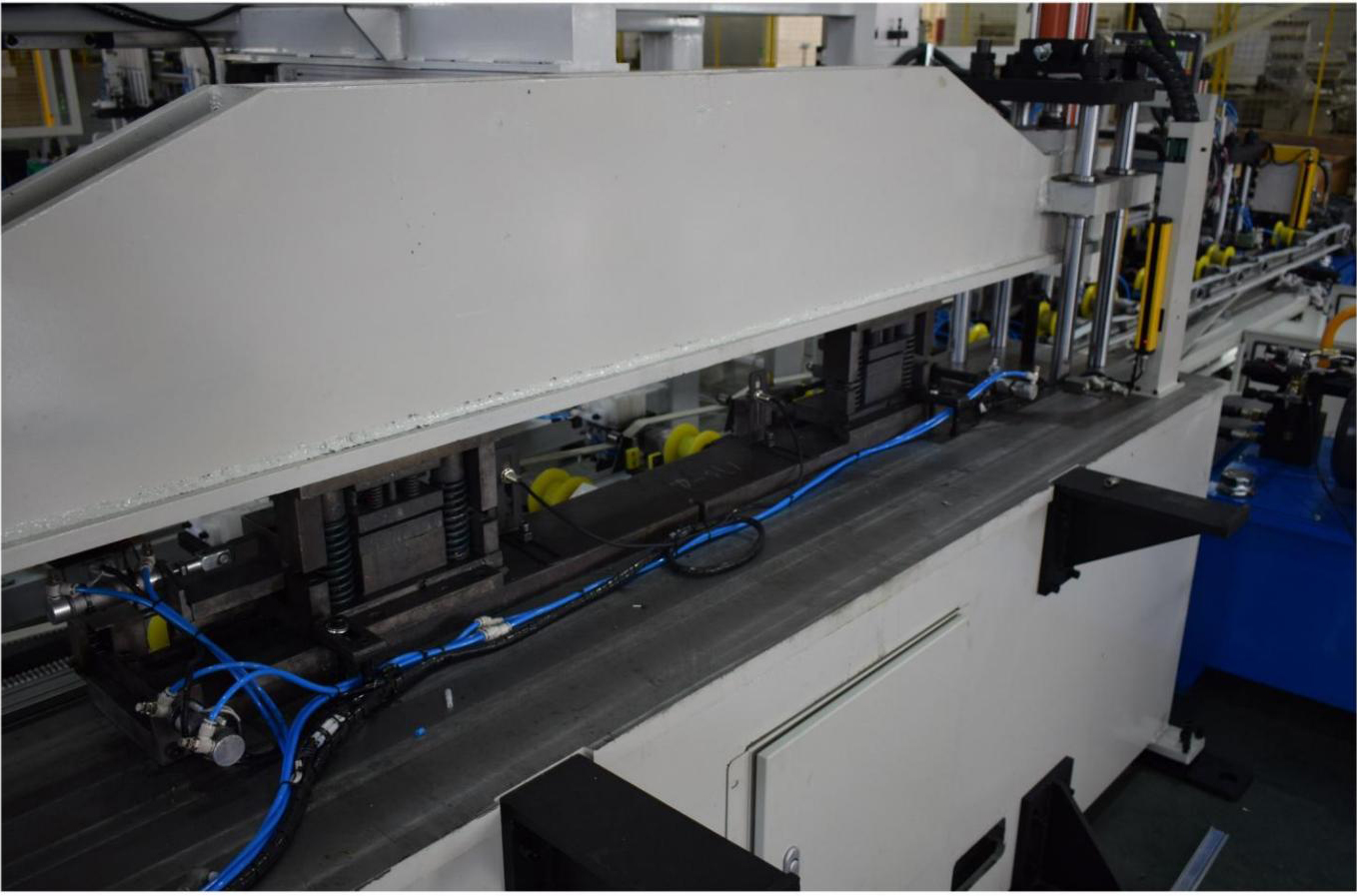

The saw blade feeding system adopts gas-liquid damping cylinder to ensure uniform feed speed, smooth movement and good cutting effect.

Using automatic spray device, the saw blade feed automatic spray, effectively cool the lubrication saw blade, prolong the service life of the saw blade.

The punch is powered by a hydraulic system with a stable and reliable pressure.

Photovoltaic frame long side four installation holes, four air holes, two drainage holes, grounding holes, grounding mark stamping, a stamping completed, improve the work efficiency.

technical parameter:

order number | project name | Long frame | Short frame |

1 | Applicable profile specifications | 3-7.5m | 3-7.5m |

2 | Bezel length | 1600-2480mm | 900-1280mm |

3 | border width | 25mm-35mm | 25mm-35mm |

4 | Frame height | 30mm/35mm | 30mm/35mm |

5 | Corner riveting point way | convention | convention |

6 | Power consumption of gas source | 0.5-0.7Mpa | 0.5-0.7Mpa |

7 | Target capacity | 800-900支/h | 800-900支/h |

8 | Cutting accuracy | 长度±0.25mm;角度±0.2° | 长度±0.25mm;角度±0.2° |

9 | Rivet accuracy | ±0.1mm | ±0.1mm |

10 | navar | PLC motion controller and servo interconnection | PLC motion controller and servo interconnection |

11 | Automatic feeding system | Transmission mode: constant speed motor, smooth operation; Delivery mode: synchronous belt; Feed mode: manually arranged on the conveying line, automatically transmitted to the feeding mechanism; Feed-in time interval: 5min Each quantity: 2 | Transmission mode: constant speed motor, smooth operation; Delivery mode: synchronous belt; Feed mode: manually arranged on the conveying line, automatically transmitted to the feeding mechanism; Feed-in time interval: 5min Each quantity: 2 |

12 | Automatic feeding and cutting machine | Automatic feeding mode: servo-electric and pneumatic manipulator; Single cut amount: 2 pieces; Cutting feeding mode: air-liquid linkage, cutting speed is adjustable; Angle adjustment mode: mechanical positioning; Length adjustment mode: CNC servo positioning adjustment, total control system display size; Head recovery method: the deceleration motor is transported to the external collection box of the equipment through the conveying line. Cutting finished product: the saw machine feeding manipulator delivers the frame to the front conveyor line. | Automatic feeding mode: servo-electric and pneumatic manipulator; Single cut amount: 2 pieces; Cutting feeding mode: air-liquid linkage, cutting speed is adjustable; Angle adjustment mode: mechanical positioning; Length adjustment mode: CNC servo positioning adjustment, total control system display size; Head recovery method: the deceleration motor is transported to the external collection box of the equipment through the conveying line; Cutting finished product: the saw machine feeding manipulator delivers the frame to the front conveyor line. |

13 | C face processing | Charging method: the feeding manipulator will send the frame to the conveying line; Delivery mode: deceleration motor + synchronous belt; Cutting force of the hydraulic press: 20T Hydraulic machining length: 1.5m-2.6m, high-speed stamping stroke is adjustable Stamping feeding mode: servo motor + pneumatic manipulator | Charging method: the feeding manipulator will send the frame to the conveying line; Delivery mode: deceleration motor + synchronous belt; Cutting force of the hydraulic press: 20T Hydraulic machining length: 0.8m-1.5m, high-speed stamping stroke is adjustable Stamping feeding mode: servo motor + pneumatic manipulator |

14 | Finished product collection part | The equipment is equipped with finished product conveying lines, using deceleration motor + synchronous belt, and conveying the frame to the receiving station. | The equipment is equipped with finished product conveying lines, using deceleration motor + synchronous belt, and conveying the frame to the receiving station. |

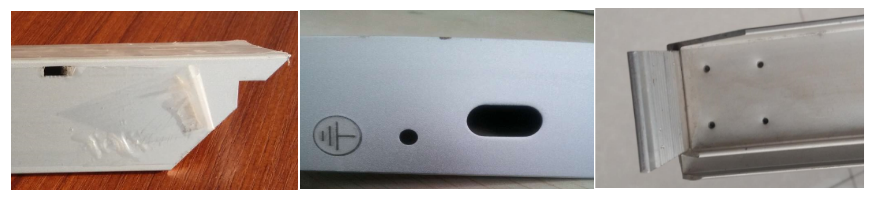

tooling samples